"Sandwich" panel and general purpose

Progressive directions and new technologies are as suitable as possible for such an industry as construction and operation of buildings. The objective reality in this area of business is that the costs of construction and operation of industrial facilities should be minimal. At the same time, the requirements for reliability, strength and thermal insulation properties of the materials used, quality and speed of construction of buildings are only growing from year to year. One of the progressive areas in this area – “sandwich” panels, the use of which saves up to 30% of total construction costs.

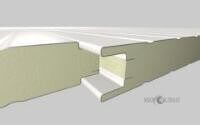

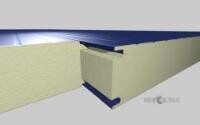

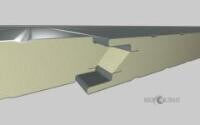

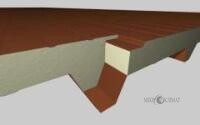

“Sandwich” panels are large multi-building structures, consisting of one or two layers of coating and insulation. They are a ready building design in which properties of all used materials are favorably combined. Currently, there are three main areas of application of “sandwich” panels: wall, roof and panels for refrigerators and freezers. These types of panels cover the entire range of construction of buildings and structures for industrial and commercial purposes.

Structures assembled from “sandwich” panels can equip almost any low-rise building, from a small personal garage or car wash to an industrial plant or warehouse of tens of thousands of square meters. The material at its relatively low cost, does not require additional processing, is easy to install and in this sense is very convenient. The service life of the panels according to the parameters laid down in them is not less than 25years.

The panels are mounted on a special power frame of the building, with the help of special selective elements. The joints between the panels are additionally sealed with a sealant with guaranteed quality.

About the main technical characteristics of “sandwich” panels

Data for design | Description and technical information |

Panel thickness | 42mm, 50mm, 60mm, 80mm, 100mm, 120mm, 150mm, 180mm, 200mm and 250mm |

Panel width | From ID 300mm ÷ 1100mm |

Continuous height of panels | From 300 mm ÷ 6300mm |

The degree of fire resistance of panels | EI15, EI45, EI60 |

Materials of panels | Galvanized metal, 0.45 ÷ 0.8mm thick |

Galvanized metal with antibacterial PVC coating, 0,45 ÷ 0,8mm thick | |

Stainless metal, 0,45 ÷ 0,8mm thick | |

Filling of panels | Mineral wool, density 120-140kg/m3 |

Polyurethane foam, density 40-42kg/m3 | |

Foam density 15-25kg/m3 | |

Covering the surface of the panels | Polyester powder paint |

Polyester powder paint with antibacterial properties | |

PVC with antibacterial properties | |

Additional filling | Special selection elements for installation of wall and ceiling panels |