. Exhaust panels

Exhaust panels are used to remove exhaust air from the room. They are performed on the thickness of the wall panel for clean rooms. They give significant useful savings in space. They are used for the needs of different types of industrial enterprises, different types of laboratories and various health care facilities. For the needs of industrial enterprises, exhaust panels with exhaust air intake from the lower zone (100%) are usually used. For the needs of health care facilities, exhaust panels with exhaust air intake from the lower and upper zone are usually used (60% from the lower zone and 40% from the upper zone). They are made with the increased requirements to tightness.

Selection of exhaust panels and their place of installation in the premises is carried out individually for the needs of the Customer.

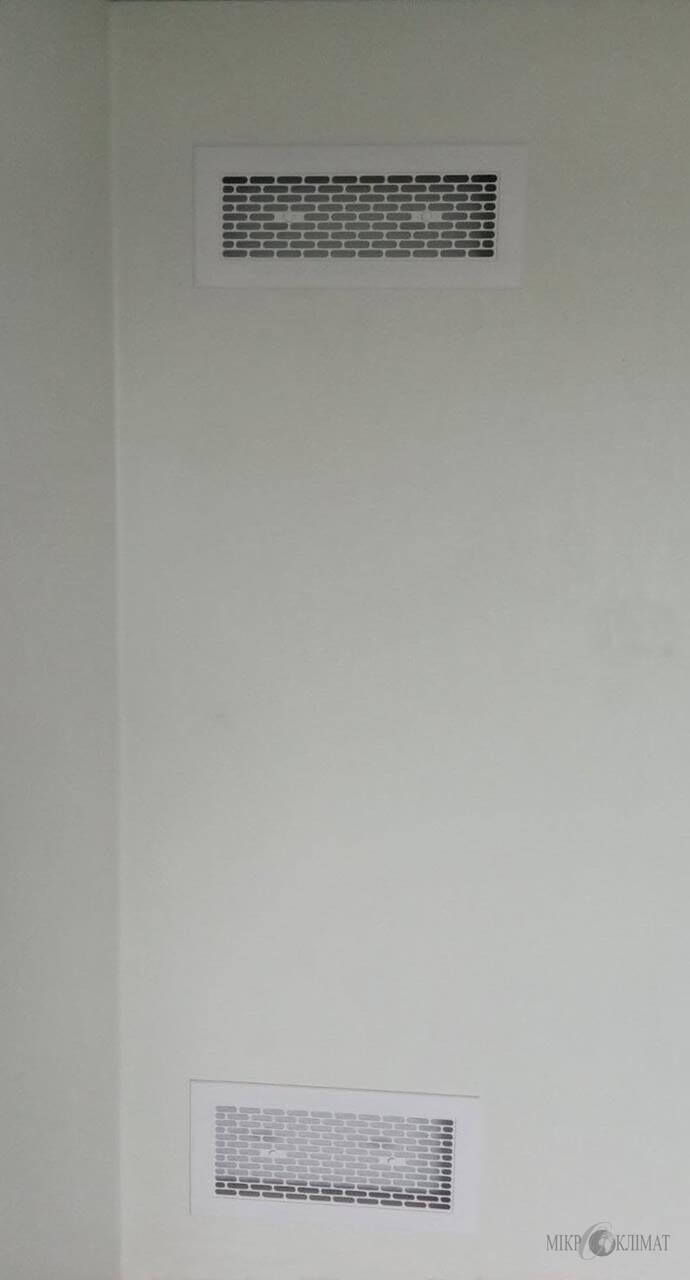

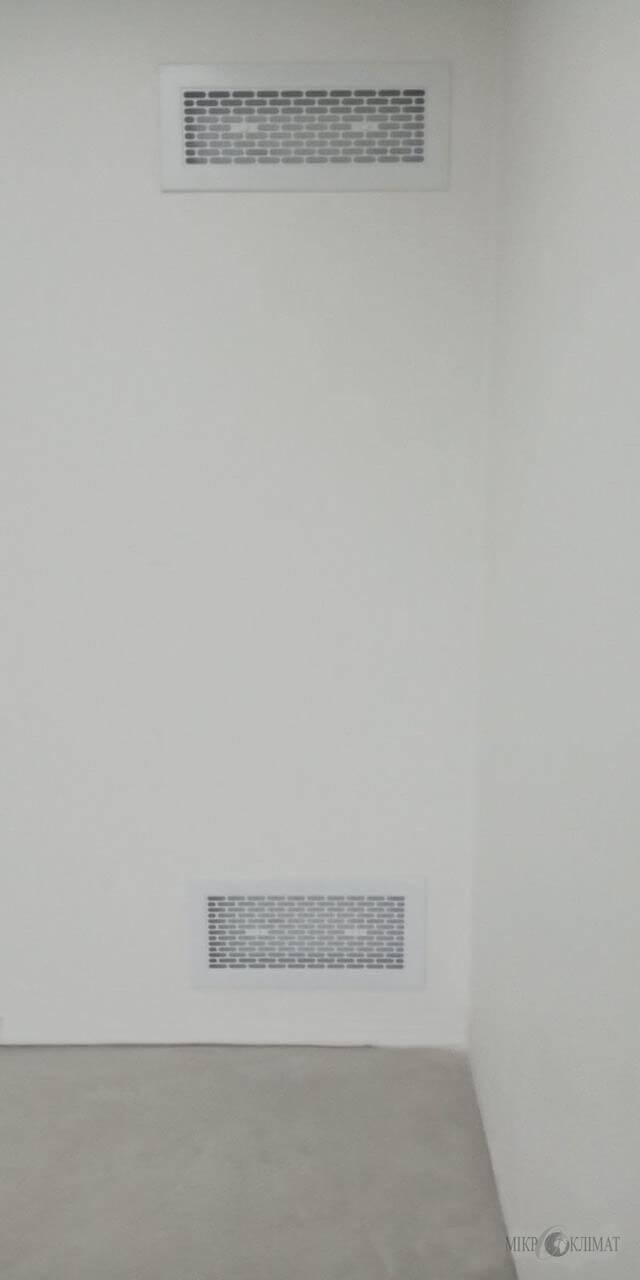

Exhaust panels consist of two externally visible elements, with the filling of the internal space between them with a special frame, adjustable ventilation grille (adjustable ventilation grilles) and elements of fastening and connection to the ventilation and air conditioning system. They can have both a standard floor version and a corner version. Structural units are designed in a hygienic design, do not have sharp corners, grooves, recesses, i.e. do not contribute to the accumulation of dust, harmful particles and bacteria.

Exhaust columns are mounted in the appropriate wall structures, by hidden fasteners. The special design of exhaust panels allows to make the hidden installation in a wall capital and a linen partition, for under finishing with various materials of the customer (ceramic tile, etc.).

The joints between the individual elements are additionally sealed with a silicone-based sealant with guaranteed quality.

The main technical characteristics of exhaust panels

Standard overall dimensions | According to the technical appendix |

Panel thickness | 60mm, 80mm |

Panel width | From 500mm ÷ 1115mm |

Continuous height of panels | From 2100mm ÷ 6300mm |

Standard types of ventilation grilles | Perforated grilles |

Adjustable perforation gratings | |

Materials | Galvanized metal, 0,8mm thick |

Galvanized metal with antibacterial PVC coating, 0,8mm thick | |

Stainless metal, 0,8mm thick | |

Aluminum sheet, 1,2mm thick | |

Filling of panels | Special galvanized frame |

Special stainless-steel frame | |

Special aluminum frame | |

Surface coating | Polyester powder paint |

Polyester powder paint with antibacterial properties | |

PVC with antibacterial properties | |

HPL-plastic, 3,0mm thick | |

Fastening of a ventilating lattice | Completely hidden mount |

Additional equipment | Automatic air flow control valve |

Mechanical valve for constant air flow control | |

Duct type air purification filter |

The elements are covered with powder paints, sintering method. Coatings characterized by superficial hardness, resistance to treatment disinfecting solutions, is not conducive to the formation of cracks and generation of microparticles from the working surface of the panel. The color of the coating can be selected according to the RAL colors for powder paint.