Laminar systems for industrial premises

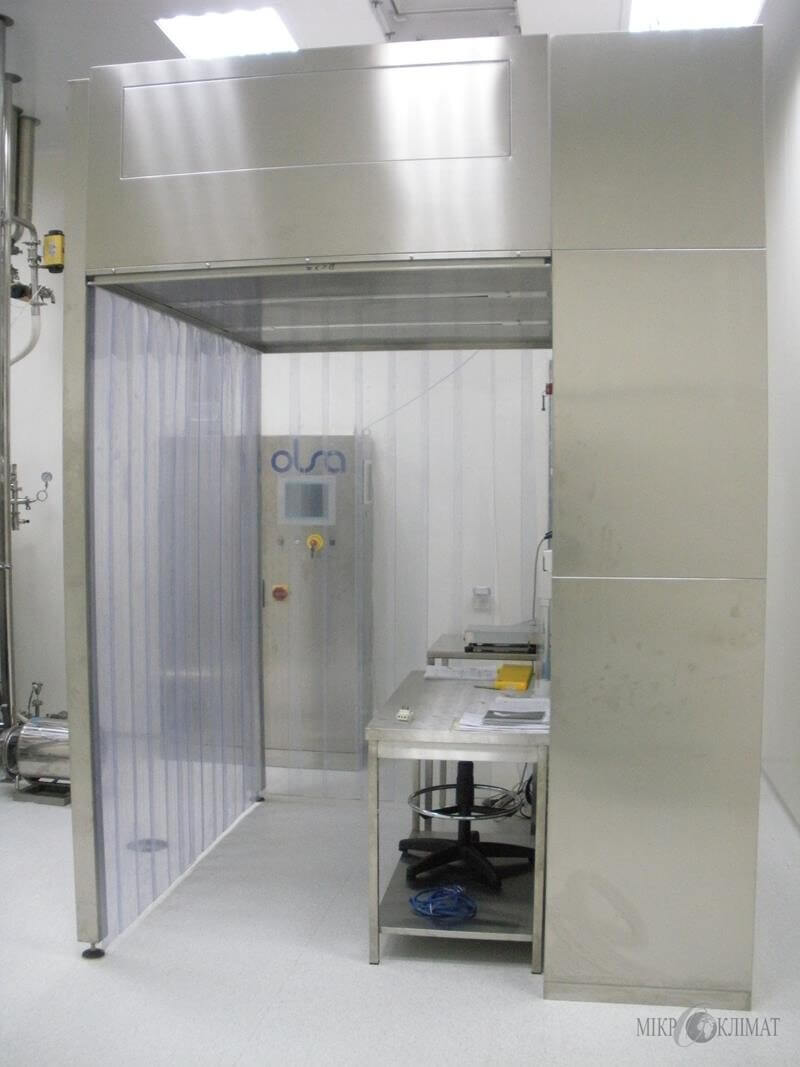

Laminar air purification systems are used in clean rooms for additional air purification and its supply directly to critical areas where products or processes are exposed to contaminants. Use of such installations allows to provide air supply of high quality only in those places where it is necessary, thus considerable economy of means in comparison with pure rooms with a laminar air stream on all space is reached. They are used for the needs of different types of manufacturing plants, different types of laboratories and various health care facilities. They are made with the increased requirements to tightness of components and level of noise characteristics.

The laminar installation consists of the tight case, the air fan, ventilating lattices, elements of tight installation of the panel air filter, elements of regulation and measurement of an air stream.

Production of laminar installations provides selection from the wide range of the sizes and is carried out individually to needs of the Customer.

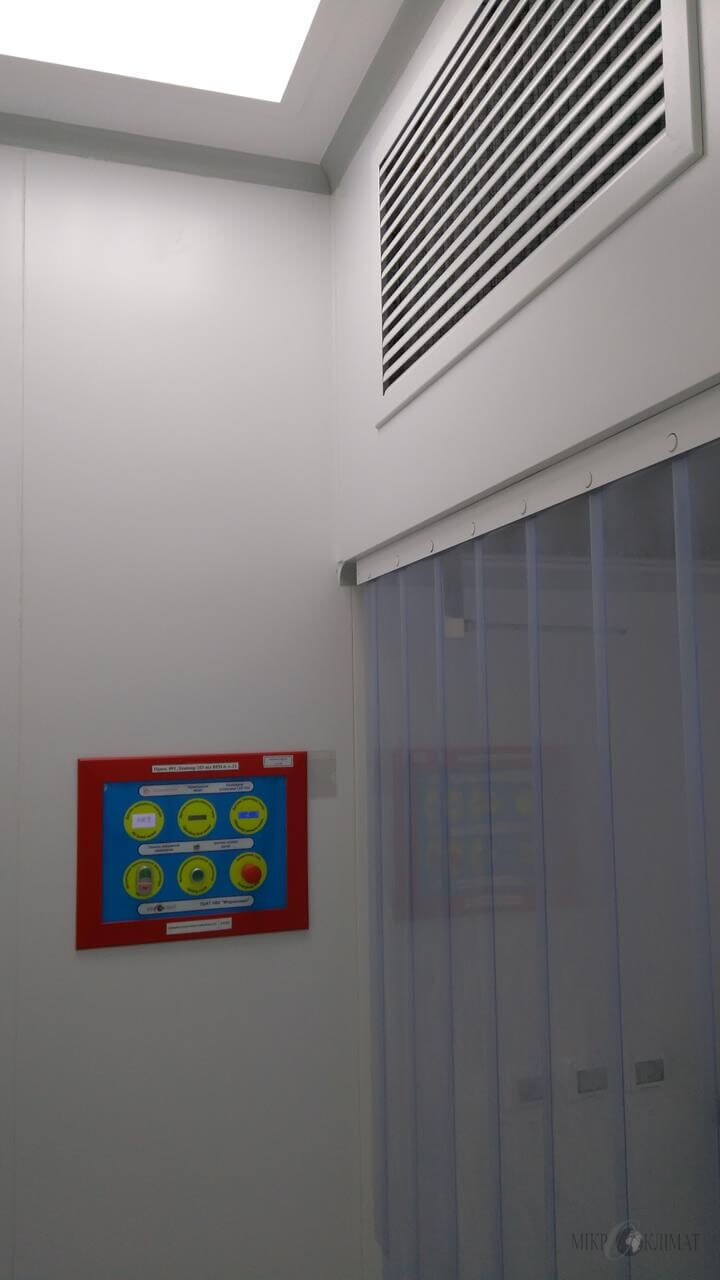

Laminar system is mounted in accordance of trained design ceiling space, through hidden fasteners.

The joints of the elements are additionally sealed with a silicone-based sealant with guaranteed quality.

The main technical characteristics of laminar systems

Overall dimensions | According to the requirements of the Customer |

Standard filter type | ERA, NERA, ULPA |

Performance materials casing | Galvanized metal, 0,8mm thick |

Galvanized metal with antibacterial PVC coating, 0,8mm thick | |

Stainless metal, 1,0mm thick | |

Filling the case | Mineral wool, density 120-140kg/m3 |

Surface coating | Polyester powder paint |

Polyester powder paint with antibacterial properties | |

PVC with antibacterial properties | |

Standard equipment | Hermetic case |

A set of ventilation grilles with hidden mounts | |

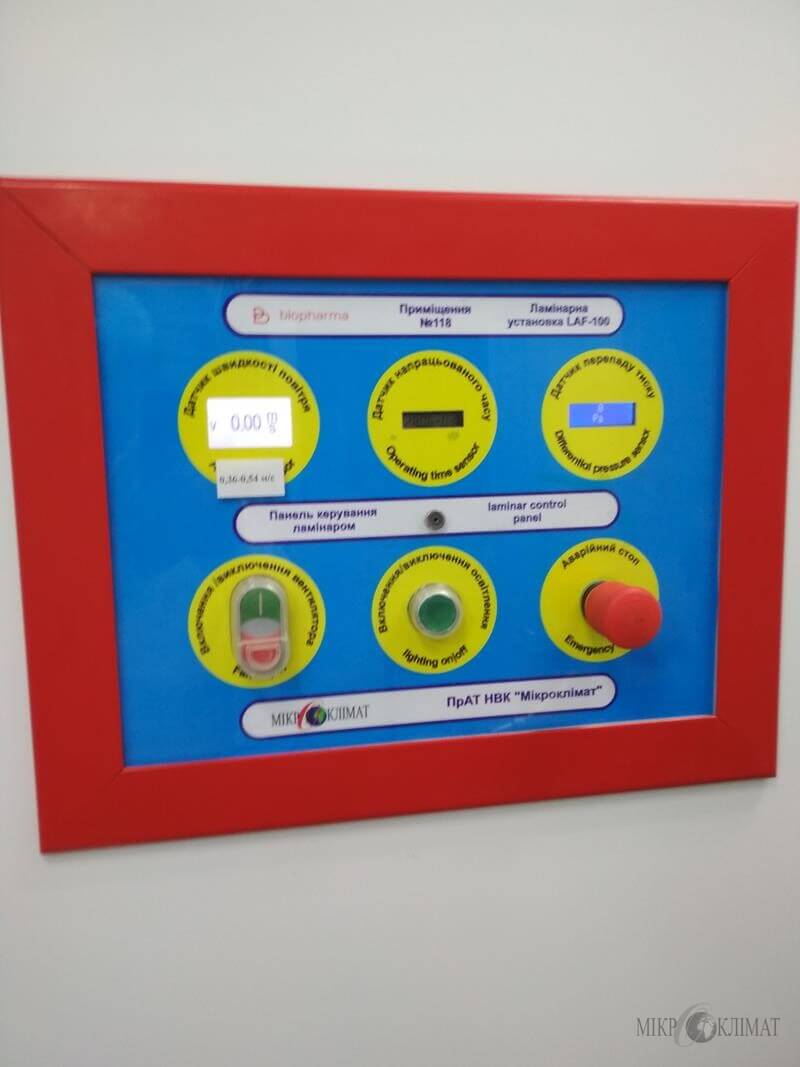

Control unit and operation indication | |

Filter intake module (filter intake modules) | |

Filter tidal module (filter tidal modules) | |

Influx fan (inlet fans) | |

Control of tightness of installation of air filters | |

Contamination control of air filters | |

Maintenance of air filters | from the side of the room |

Optional equipment | Glass fence of the working area |

PVC curtain around the perimeter of the work area | |

Lighting in the work area | |

Additional supports for movement | |

The sensor of control of speed of an air stream at an exit from a laminar installation | |

Pollution control sensor of the filter element | |

Sensor for monitoring the number of hours worked | |

Giving an electrical signal about the contamination of the filter element | |

Remote control unit and indication of operation on the swivel bracket |

The elements are covered with powder paints, sintering method. Coatings characterized by superficial hardness, resistance to treatment dis infecting solutions, is not conducive to the formation of microcracks and the generation of particulate from the working surface. The color of the coating can be selected according to the RAL colors for powder paint.