Transmission window

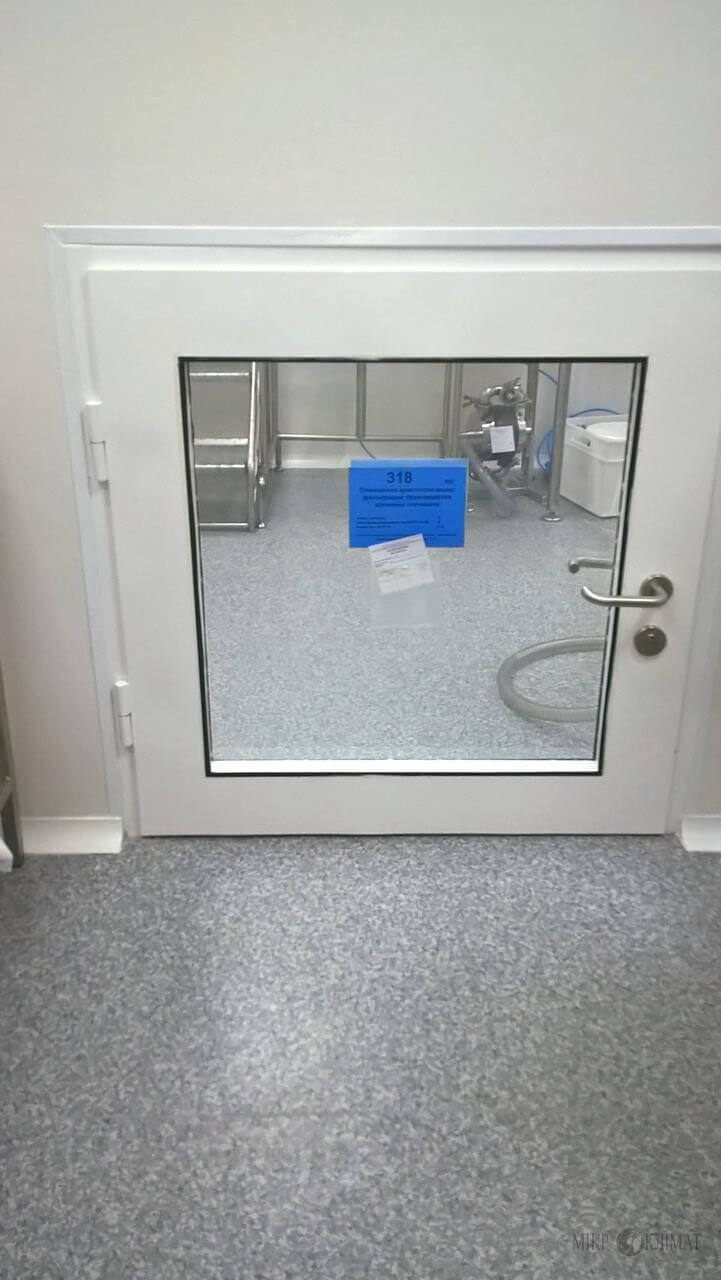

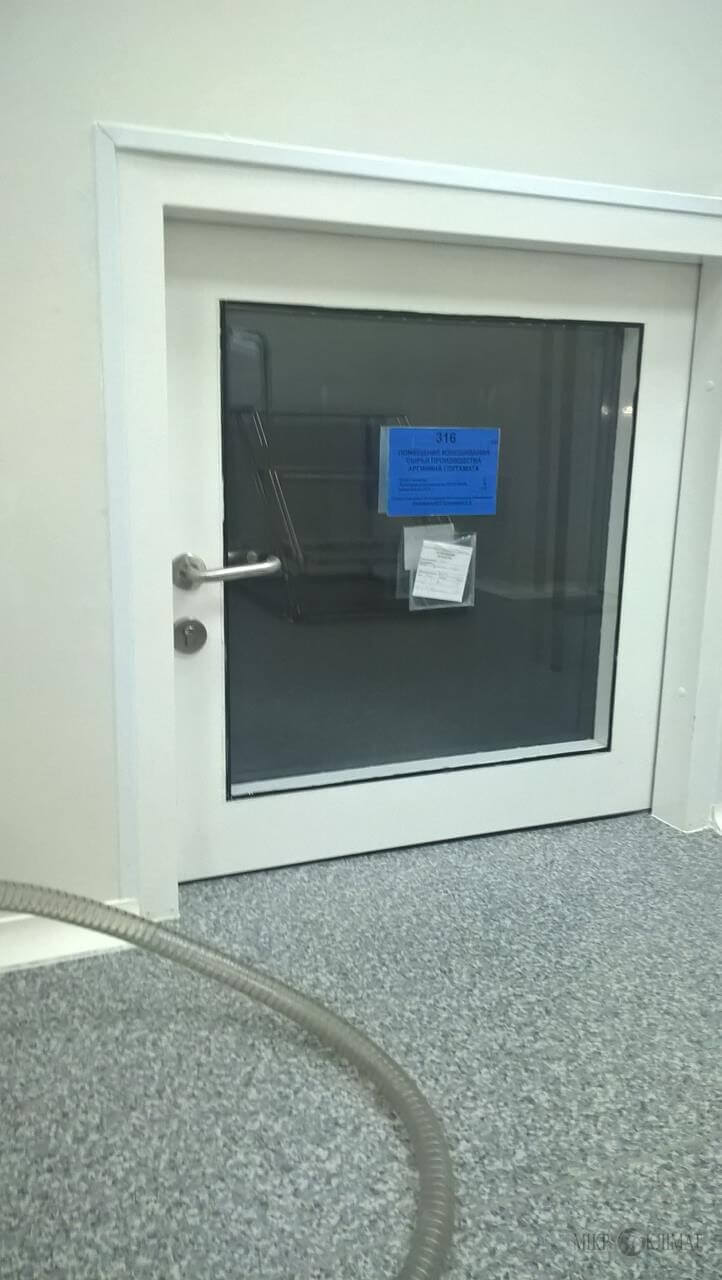

The transfer window is used to transfer materials between adjacent rooms. They are used for the needs of different types of industrial enterprises, different types of laboratories and various health care facilities. They are made with the increased requirements to thermal and sound insulation, and also tightness of a door cloth concerning a door box.

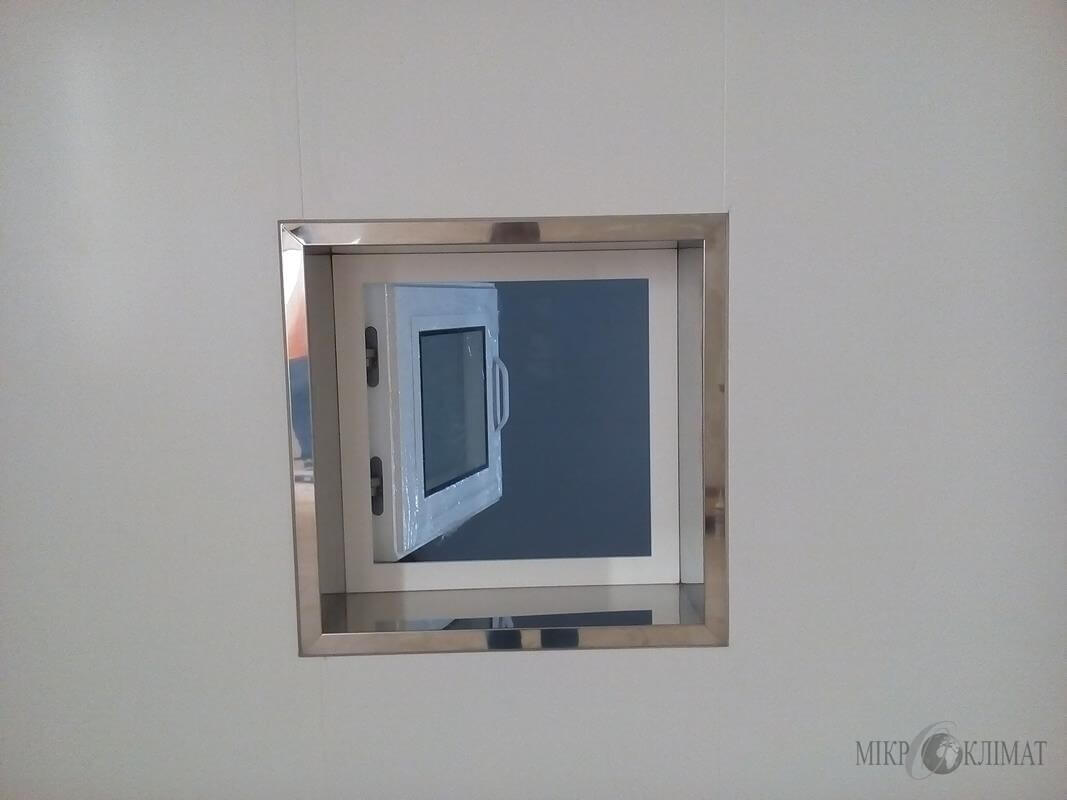

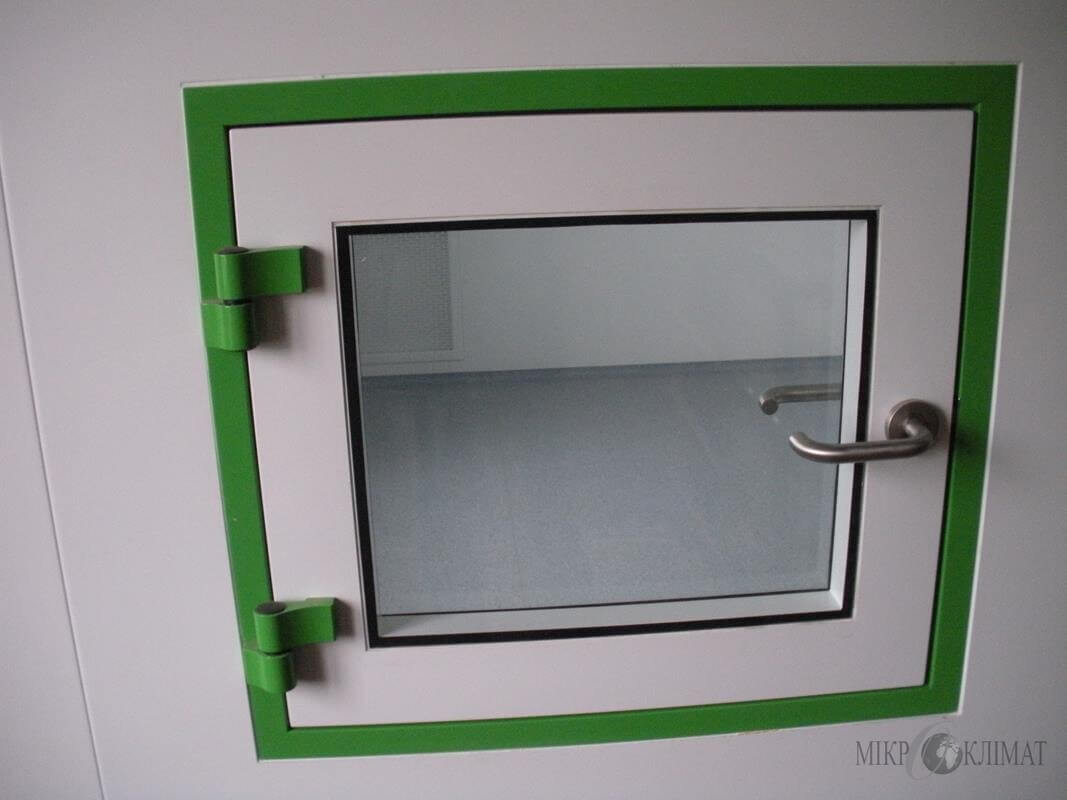

The transfer window consists of a door frame, a door cloth and elements of door accessories. The door frame is made of power aluminum or galvanized profile with an additional protective surface coating. The door leaf consists of two externally visible elements, with the internal space between them being filled with heat-insulating material. Transmission windows are made both solid and with built-in sealed windows. The double-glazed window has a tight design and is made on the thickness of the door leaf, without protruding elements. Structural units are designed in a hygienic design, do not have sharp corners, grooves, recesses, i.e. do not contribute to the accumulation of dust, harmful particles and bacteria. Door fittings of well-known European brands are used for the production of transmission windows.

The production of the transfer window involves selection from a wide range of sizes and is carried out individually to the needs of the Customer.

Transmission windows in any types of wall designs are mounted.

The joints between the individual elements are additionally sealed with a silicone-based sealant with guaranteed quality.

The main technical characteristics of transmission windows

The thickness of the transmission window | 42mm, 60mm |

Transmission window width | From 300mm ÷ 1300mm |

The height of the transmission window | From 300mm ÷ 13 00mm |

Materials of a door frame | Power aluminum anodized profile |

Power galvanized profile | |

Materials of a door cloth | Galvanized metal, 0,8mm thick |

Galvanized metal with antibacterial PVC coating, 0,8mm thick | |

Stainless metal, 0,8mm thick | |

Aluminum sheet, 1,2mm thick | |

Filling of a door cloth | Mineral wool, density 120-140kg/m3 |

Polyurethane foam, density 40-42kg/m3 | |

Surface coating | Polyester powder paint |

Polyester powder paint with antibacterial properties | |

PVC with antibacterial properties | |

HPL-plastic, 3,0mm thick | |

Standard equipment | Door frame with elastic seal |

Door leaf (deaf/window block) | |

Door internal adjustable hinges | |

Mechanical door lock | |

Door handles | |

Additional equipment | Stopper of a position of a door cloth |

Stainless metal protective pads | |

Electromechanical lock | |

Door frame kit for openings on both sides of the door block | |

Lead sheet (on one or two sides), 0,5-4,0mm thick, to meet the conditions of X-ray protection | |

X-ray protective sheet GKL (on one or two sides), 12,5mm thick |

The elements are covered with powder paints, sintering method. Coatings characterized by superficial hardness, resistance to treatment disinfecting solutions, is not conducive to the formation of microcracks and the generation of particulate from the working surface. The color of the coating can be selected according to the RAL colors for powder paint.